|

|

|

|

|

|

Welcome to the Australian Ford Forums forum. You are currently viewing our boards as a guest which gives you limited access to view most discussions and inserts advertising. By joining our free community you will have access to post topics, communicate privately with other members, respond to polls, upload content and access many other special features without post based advertising banners. Registration is simple and absolutely free so please, join our community today! If you have any problems with the registration process or your account login, please contact us. Please Note: All new registrations go through a manual approval queue to keep spammers out. This is checked twice each day so there will be a delay before your registration is activated. |

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#1 | ||

|

FF.Com.Au Hardcore

Join Date: Jan 2009

Location: Victoria

Posts: 877

|

I recently suspected that my Focus had a split PCV hose, causing a vacuum leak, which seems to be a common problem on the LS-LT Focus. The symptoms were: high revving on start-up (~2500rpm), a higher-than-normal, unstable idle, and intermittent hanging revs on deceleration.

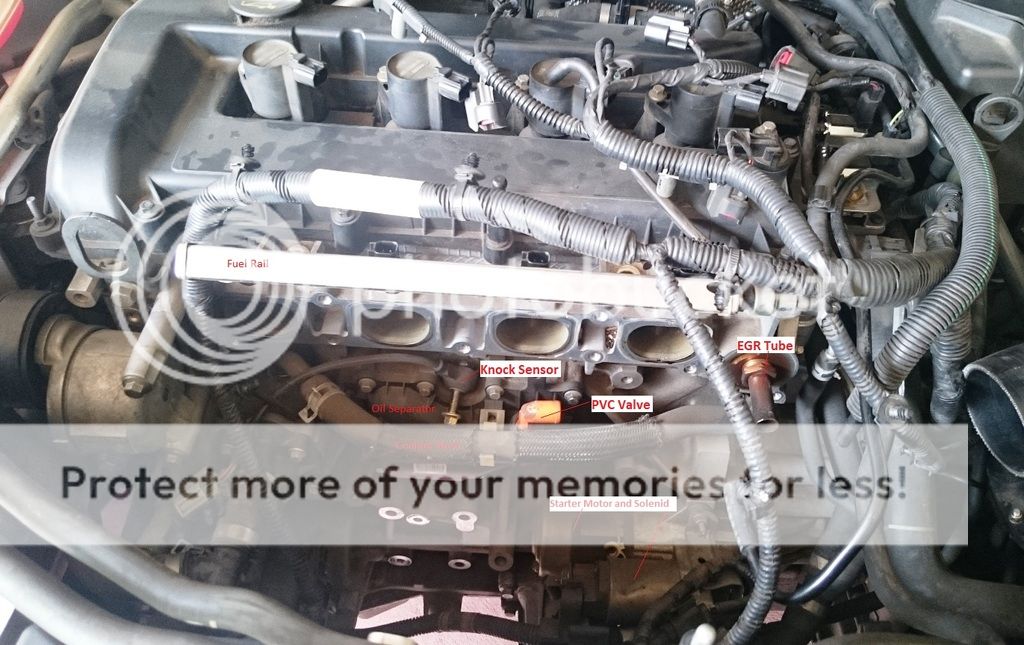

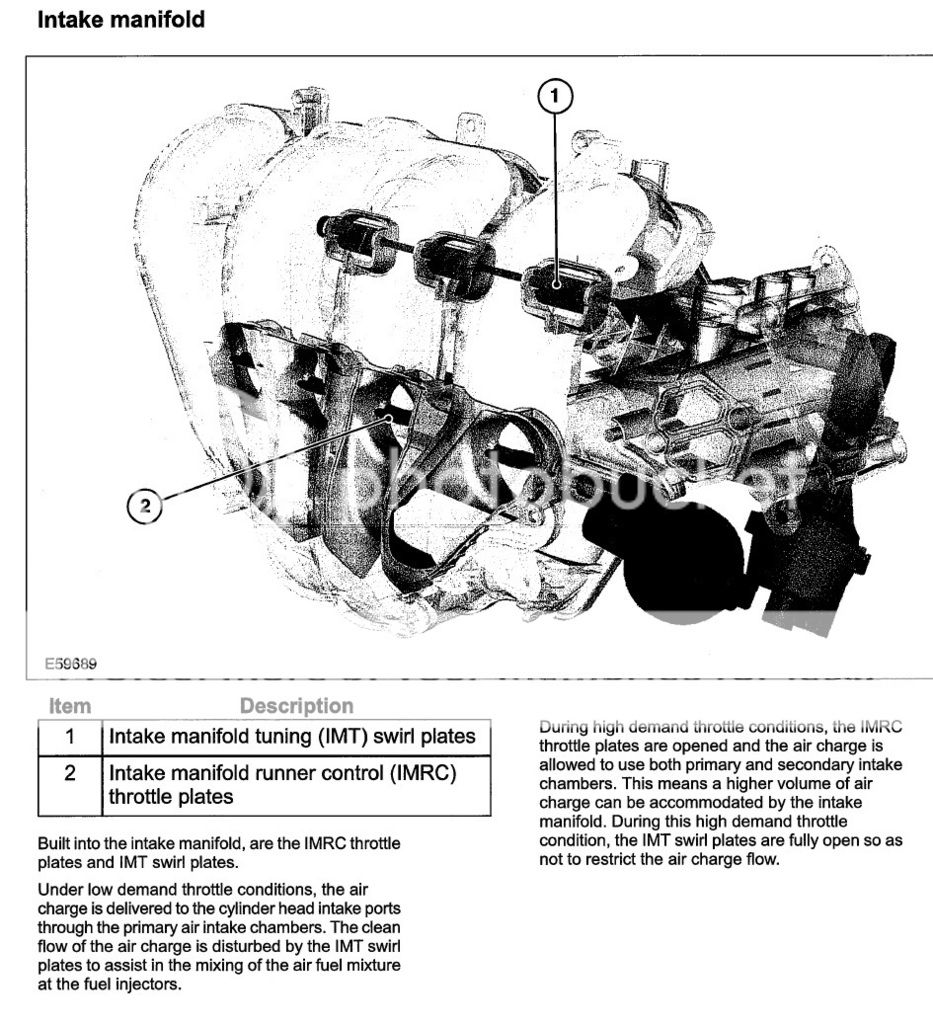

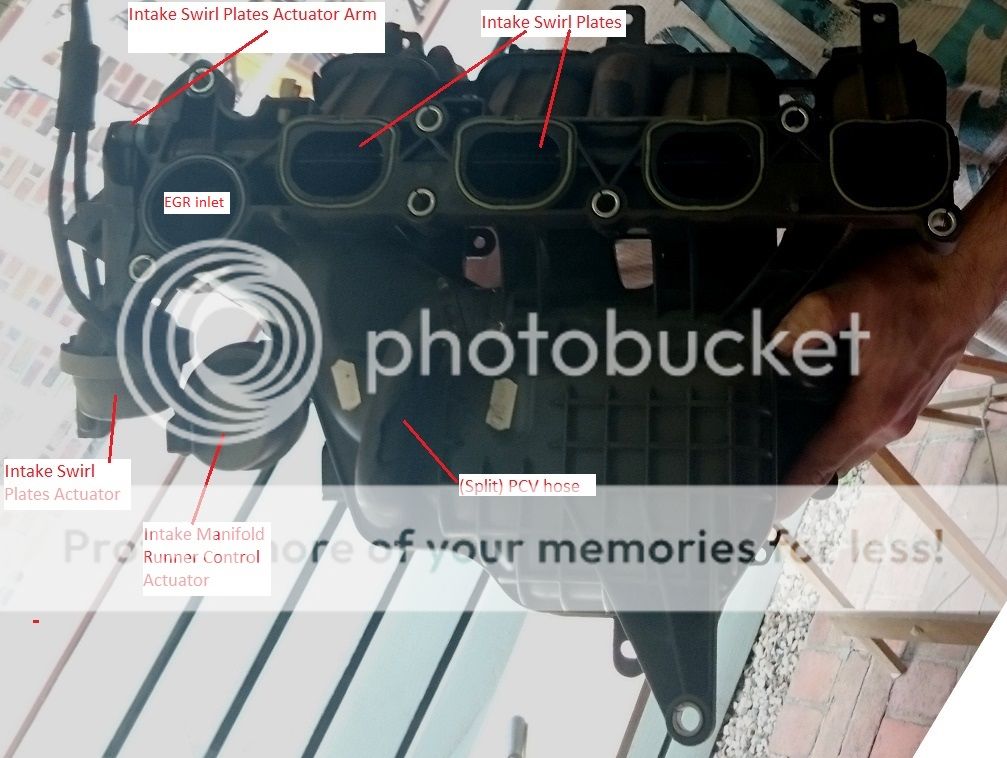

The big problem with this hose is its location Ė underneath the intake manifold. Visibility of the hose is very poor. And replacement of the hose involves removal of the intake manifold. Having said that, one forum member (20focus05) was able to replace the hose by removing the starter motor and attacking the job from below, without removing the manifold, so I guess that way is possible too. I confirmed my suspicions by spraying some brake cleaner (caution: flammable), at the PCV hose between the 3rd and 4th intake manifold runner, with the engine idling. Sure enough, the revs increased, followed by a lean response, causing the engine to nearly stall. I went down to Ford and bought myself a PCV hose, $84+ GST for a small piece of rubber hose. And for good measure, bought a PCV valve, which was only about $20. I set aside Sunday, along with a mate, to give this job a crack. Hereís how we went about it: 1. Depressurised fuel rail by removing fuel pump fuse with engine running (itís a returnless system), followed by attempting to start the car a few more times. 2. Disconnected battery negative 3. Worked our way around the manifold, disconnecting the intake hose, the throttle body, the dip stick tube, MAP sensor (front-bottom-left of manifold), the knock sensor (under front right), the wiring harness clips, various vacuum lines, including the brake booster, IMRC + IMT vacuum lines (see below). 4. Then undid the 8 retaining bolts. Some of these were a real pain, especially bolt number 5 (see diagram below). Plenty of ľĒ drive tools here, along with patience. There is a very helpful youtube video https://www.youtube.com/watch?v=H_DnE4YlZRg which gives some good advice (yes, this is a US Focus but the intake manifold is very similar).  5. As we withdrew the manifold, we lifted up the loosened fuel rail a little (without fully removing it), helped to give an extra bit of clearance. And as the manifold comes out the top, donít forget to disconnect the PCV hose, as well as check for any wiring, sensors, of vacuum lines that you have missed. The PCV hose connects from the PCV valve to an inlet on the rear-bottom-left of the intake manifold. The PCV hose was screwed. It had a nice big split, potential to cause a large vacuum leak.  And whilst the manifold was out, it was a good time to replace the PCV valve. Push in the two clips either side of the black retaining ring and withdraw the PCV valve simultaneously. You will encounter some resistance from the o-ring seal.  The result: smooth, stable idle, no hanging revs and normal RPM on startup. Iím calling it a fix. I also became interested in the functions of the 2 vacuum actuators on the manifold. After some research, I found info on the two systems: 1. The intake manifold tuning swirl plates, which can narrow the intake passage to increase airflow speed and also create turbulence to aid in better air-fuel mixture 2. The intake manifold runner control, which changes the effective length of the intake runners and air intake volume.

|

||

|

|

|

|

|

#2 | ||

|

FF.Com.Au Hardcore

Join Date: Jan 2009

Location: Victoria

Posts: 877

|

Some further information in regards to testing the solenoids that control the intake manifold swirl plates / intake manifold runner control:

The solenoids look like this, and are located next to the cylinder head, on the passenger side:  One solenoid actives the IMRC and the other one activates the IMT / Swirl Plates. Each solenoid is supplied by vacuum from the intake manifold. When commanded 'on' by the PCM, the solenoid will then send this vacuum to the IMRC / IMT actuators. The most common problem we see on these solenoids is a P2008 code, Intake Manifold Runner Control Circuit Open Bank 1. The problem often starts of as an intermittent fault and is well documented here on the forums. According to the workshop manual, "the solenoid for the intake manifold switching system is supplied with either the maximum voltage or zero voltage, i.e. the valves are either fully open or fully closed. Actuation depends on the engine speed and the engine load." A definitive test for the solenoid would be to manually supply vacuum to the solenoid (eg a hand-held vacuum pump with a gauge), and then supply voltage the solenoid (ie. command it 'on') using a PowerProbe or similar, then watch the vacuum suddenly drop / bleed off. An alternative, quick and easy test would be to actually switch the solenoids over and see if the problem rectifies itself. |

||

|

|

|

| This user likes this post: |

|

|

#3 | ||

|

FF.Com.Au Hardcore

Join Date: Jan 2009

Location: Victoria

Posts: 877

|

For anyone taking on this job, here is another good intake manifold removal guide (on a mondeo which is only slightly different): http://www.youtube.com/watch?v=vBxm5QjD0PY

And a PCV and hose replacement: http://www.youtube.com/watch?v=-TR4pZdXZpg |

||

|

|

|

|

|

#4 | ||

|

Starter Motor

Join Date: Apr 2015

Posts: 3

|

Hey DZ,

I know this is an old thread, and now that your focus is dead ytou might not be on here, but if you are, and you still have photos, i would REALLY appreciate them ! Recently had the p2008 code and replaced a sensor in the manifold, now im getting a p1549 code, which seems to be very similar. Looking to replace the solenoids now your thread looks like a massive help! |

||

|

|

|

|

|

#5 | ||

|

FF.Com.Au Hardcore

Join Date: Jan 2009

Location: Victoria

Posts: 877

|

Hi Steezy, here is a pic of the solenoids:

|

||

|

|

|

|

|

#6 | ||

|

Starter Motor

Join Date: Oct 2014

Posts: 7

|

I have been searching all over for info on changing the pcv hose from below by removing the starter motor. I have sighted the split hose through the gap in the manifold runner at the top and managed to get a bit of thick adhesive tape over the hose which has instantly cured the high idle at start and hanging throttle. Has anyone changed it from below or is it just a myth? any info or links apreaciated

|

||

|

|

|

|

|

#7 | ||

|

Regular Member

Join Date: Aug 2013

Posts: 90

|

Hi I have changed my pcv hose by taking the starter motor off. I can be done but itís a painful job.

|

||

|

|

|

|

|

#8 | ||

|

Starter Motor

Join Date: Oct 2014

Posts: 7

|

Thanks, would you do it that way again or take off the inlet manifold? I have not done the job yet as I am still awaiting delivery of the hose however I have managed to get a bit of duct tape onto the split hose which remarkably has stopped all the issues and seems to be holding .

|

||

|

|

|

|

|

#10 | ||

|

Starter Motor

Join Date: Oct 2014

Posts: 7

|

Did the hose by removing the intake, Car is a 2006 Zetec Auto. Released all the loom clips and plugs and then all the manifold bolts. Never touched the fuel rail. l then had enough room to get long nose pliers in, pull off the old hose and get the new on. A few scraps on my hands but went real smoothly with no dramas thanks to the info here. Got the hose from china

https://www.aliexpress.com/item/1005...27424c4dRJsktK |

||

|

|

|